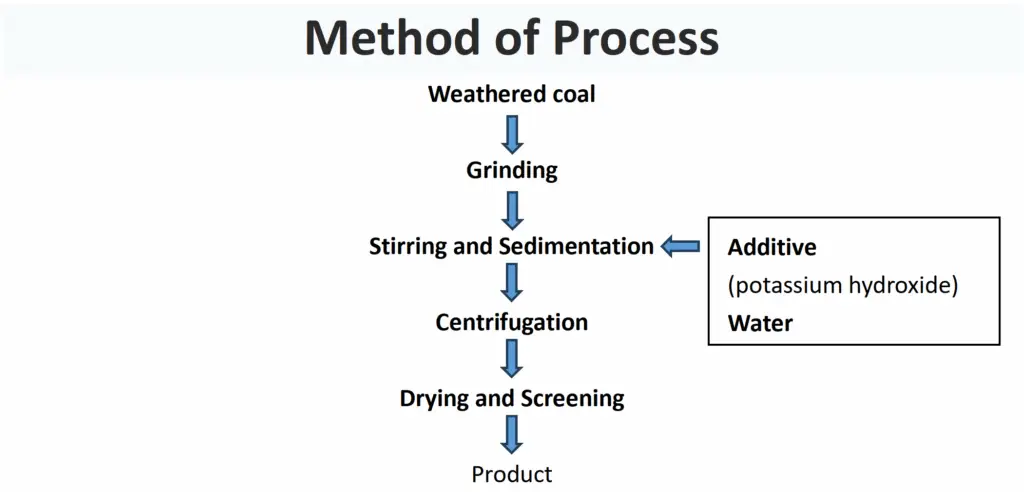

Production Process Description

1.Weathered coal

The raw material used in the production of potassium humate is weathered coal, which is weathered coal of the same type but different origin.

Transported by car to the factory raw material warehouse for storage.

2.Grinding

During production, the raw materials are sent to the belt conveyor by the loader to the crusher for processing and breaking.

The crushed raw materials are lifted into the mixing tank by the elevator.

3.Stirring-Sedimentation

Adding potassium hydroxide and water into the stirring reaction tank for stirring, the temperature of the stirring tank is controlled at 60~80 degrees, and the reaction time is maintained for a while after the stirring.

After that, send the liquid to the primary sedimentation section for coarse slag filtration, and then enters the secondary sedimentation.

4.Centrifugation

The deposited liquid is injected into the centrifuge by the pipeline pump for third level slagging separation, and the finished liquid is pumped into the finished product box for storage.

5.Drying and Screening

Enter the drying stage through the pipeline, inject each drying box and liquid storage box in the workshop respectively, and then dry by the drying drum and fall into the finished product conveyor belt, and then mix evenly through the elevator into the drum scieve and swing scieve

6.Product

The finished products are sent into silo by the elevator, and then packaged. After sampling by the quality inspector, they are sent to the inspection area of the finished product workshop. After passing the test, they are transferred to the qualified area for storage and sale.

The production process is a single raw material processing, there is no cross-contamination risk.